Plastic Tank Installation Instructions

Underground Plastic Tank Installation | Above Ground Plastic Tank Installation

Underground Plastic Tank Installation

EXCAVATION

- Select site with good sub-soil drainage.

- Allow clearance around the tank to properly place and compact backfill around the lower half of the tank.

- Provide well-compacted or undisturbed bedding of sand/gravel mixture or clean, granular soil: 6″ minimum in rock terrain. Shape bedding to suit underside of tank.

PLACING THE TANK

- Check before placing tank:

- Serial number (for Warranty Form).

- Orientation of inlet and outlet.

- Shipping damage.

- User a pipe level across access cover to level inlet and outlet. It is important that the outlet is below level of inlet.

CAUTION: Handle with care. A severe impact could crack the tank, especially in cold weather.

AVOIDING FLOTATION OR DISTORTION

- Poly tanks risk floating or distortion at the base if pumped out during periodic high water table. Keep tank partially filled during extreme wet conditions.

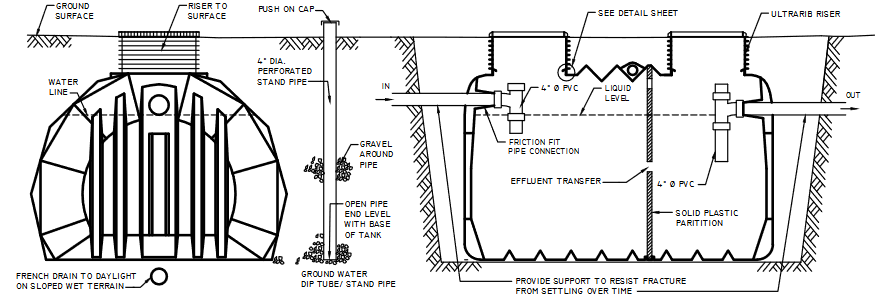

Fill after installation. - For testing water table level, install vertical length of 4″ perforated drainage pipe beside tank with removable cap above grade level. Affix label provided to standpipe.

*AVOID PUMPING TANK OUT BELOW WATER TABLE. If on sloped ground, run drainage line from under tank out to daylight, downhill from tank.

BACKFILLING

- Tank must be backfilled when either empty or no more than 30% full.

No water is required for the backfilling process. If filled for leak testing, drain tank to 30% or less prior to backfilling. - Backfill with 12″ maximum layers of granular soil or clean fill and trample evenly.

NO CLAY BACKFILL

Important: Ensure backfill is properly placed and compacted around the lower half of the tank. Do not machine compact close to tank. Do not dump large volumes of fill close to tank. - Check levelling of tank periodically.

- Be sure to compact backfill under the inlet and outlet pipe connections. Add support under pipes to resist potential pipe fracture from settling of backfill over time.

- If tank is warm from sunlight, allow to cool before completing backfilling.

- Use waterproof tape to seal lids if no riser.

PIPE CONNECTIONS:

- Make connections to tank only when tank is unlikely to shift during remaining backfilling. Use ‘Fernco’ type rubber couplings.

- All water tanks must be vented with minimum 2″ diameter pipe.

- Install 90 degree elbows at outlet bulkhead fittings to allow pipes to deflect with tank expansion (water tanks).

- USE MIN. 3 FT. FLEXIBLE HOSE FROM PUMPS TO ALLOW MOVEMENT (IF INSTALLED)

INSTALLATION CONSIDERATIONS:

- Tanks are for burial. Consult factory for above ground installs.

- Unless otherwise approved, tanks are rated for up to TWO FEET of earth cover – 300 lbs./sq.ft.

- SUPERTANKS are rated for up to FOUR FEET of earth cover – 480 lbs./sq.ft.

- FLOUT DOSING TANKS are rated for up to FOUR FEET of earth cover – 480 lbs./sq.ft.

- Do not locate under pathway of vehicles or heavy equipment.

- Keep away from large roots and rocks.

- Avoid placing tank in areas with high water table. Use reinforced tank in high water table location.

- Avoid placing tank in wet clay soils.

- Deflect surface run-off away from tank area. Fresh backfill is porous. Runoff can back up around tank.

Download Underground Tank Installation PDF

Note – Installation Instructions may vary in different jurisdictions. Consult factory if outside British Columbia.

* IMPORTANT: WARRANTY VOID IF INSTRUCTIONS NOT EXPRESSLY FOLLOWED.

Above Ground Plastic Tank Installation

WHAT BASE IS REQUIRED?

- A firm, level base that is continuous under the entire tank is required.

- Base can be sand, fine gravel, clean dirt, cement or properly supported and closely placed planks.

- Pebbles larger than half inch should be removed.

- Ensure the tank has not settled and remains vertical after filling.

CAN A PLATFORM BE USED?

Yes, however, the tank bottom must be continuously supported, e.g. with two layers of ¾ inch plywood nailed to a suitable support structure. In the interest of safety, an engineer should be consulted.

NOTE – Weight of water is 8.33 pounds per US gallon or 10 pounds per Canadian gallon

HOW HEAVY ARE THE TANKS?

- For a rough guide, the weight of above ground tanks is obtained by taking the gallon size and dividing by five. E.g., a 1000 gallon tank will weight approximately 200lb.

- For underground tanks, take the gallon size and divide by three.

ARE THEY EASY TO HANDLE?

- All tanks can be moved by pick-up truck or trailer.

- Polyethylene is a very resilient material and damage is unlikely to occur during careful handling and transportation.

- Extra care must be taken in extreme cold weather because the tank will be harder and more brittle.

CAN I PUT PRESSURE IN THE TANK?

NO! Polyethylene tanks must be open to atmosphere or vented at all times. They can be used to provide a head of water by mounting at a higher elevation but cannot be subjected to any external pressure source. Use a float valve on the inlet if necessary.

WHAT ABOUT ALGAE GROWTH?

Algae growth is promoted by light penetration into the tank. Algae growth can be reduced by locating the tank away from sunlight and choosing a darker tank colour and by disinfection.

CAN THE TANKS BE BURIED?

- Tanks are manufactured specifically for either above ground or below ground use.

- Above ground tanks have smooth sides and are for ground level mounting only. They can, however, be dropped into the ground to a depth of 20% of the tank height to reduce the above ground profile.

WHAT FITTINGS COME WITH THE TANK?

- Most above ground water tanks are fitted with a 1 inch or 2 inch female threaded pipe connection at the bottom and a 16 inch access cap at the top. Access caps have breather valves that let air in

and out as the water level changes. Your local plumber or plumbing store can help you with

making the proper connections. - Check that bulkhead drain/outlet fittings are tight onto the tank. The lock nut on the fittings has a reverse thread to prevent it coming loose when tightening external connections.

- To prevent risk of stripping, hand tighten threads several turns to make sure threads are lined up. Check for leaks when the tank is filled and tighten just enough to stop any leaks. Excessive tightening may strip the pipe threads or crack the bulkhead fittings which will then have to be replaced.

- Additional connections for inlet pipes are added separately to customer requirements.

- For approximate pipe sizing refer to Pipe Sizing Chart.

DOES SUNLIGHT AFFECT THE TANKS?

- Over time, exposure to sunlight causes the plastic to harden which makes it more prone to cracking if the tank receives a heavy blow.

- All Premier Plastics tanks are impregnated with an ultraviolet inhibitor that slows this hardening effect.

- Darker colour or black tanks will generally last longer.

WHAT ABOUT COLLECTING RAIN WATER?

- Collecting rainwater is an excellent way to bridge periods of short water supply.

- A filter basket should be used to screen out leaves, twigs, and debris coming from the eaves troughs.

- Water for drinking, cooking, and dish-washing must of course be boiled or disinfected.

- Clean rainwater can be used for large volume uses such as toilet flushes, laundry, showers, washing vehicles, and watering the garden.

- Water levels can be checked using a ‘Pneumatic Dipstick’ level gauge from Premier Plastics.

HOW LONG IS THE WARRANTY?

- All above ground tanks carry an eight year warranty, however, you can expect many more years of service.

- All underground water tanks and septic tanks carry a ten year warranty. Polyethylene will virtually last forever underground.

- Complete the warranty form and return to Premier Plastics Inc.

ARE THE TANKS SAFE FOR DRINKING WATER?

- YES – tanks are manufactured from food grade polyethylene and meet specifications contained in FDA regulations 21 CFR 177.1520(c)3.1, NSF Standard 61 and CSA 6861-05.

- Maintaining the quality of water in the tank is of course your responsibility. Information on water quality can be obtained from water supply companies, well drillers, or public health departments. Factory tanks are clean but not disinfected.

- Small particles of polyethylene may be found in the bottom of a new tank. These occur when cutting holes for fittings, and will float to the surface when filled or can be vacuumed out.

WILL I NOTICE A DIFFERENCE IN TASTE?

- To keep the water fresh, your piping should be connected so that incoming water is always flushing through the tank.

- Water that has been sitting in any type of vented container for a period of time will develop a ‘flat’ taste. This is because air in the water has been lost. This can be partly overcome by half filling a closed vessel and shaking it vigorously to put air back in.

HOW WILL A STORAGE TANK HELP A SLOW PRODUCING WELL?

- Many people are experiencing reduced flow rate from their wells. Well pumps are usually sized water “on demand”, i.e. If your bathtub fills at 5 gallons a minute then the well must produce water at 5 gallons a minute for the time the bath is running.

- A storage tank allows short periods of high demand to come from the tank and not directly from the well.

- A family using 400 gallons per day would need their well to produce no more than 400 gallons over 24 hours if a storage tank is used. On average, a well needs only to produce half a gallon a minute every minute for 24 hours to supply the family.

- A common practice is to dump a truckload of water down a slow producing well. If water deliveries were put into a storage tank no loss from seepage would occur, resulting in cost savings.

- Sizing and system layout can be obtained from your local well driller.

WHAT HAPPENS IF MY TANK FREEZES?

- It is unlikely that a partially full tank will split. The walls will swell under the pressure of ice. A tank will start to freeze only during extended periods of cold weather.

- Piping should be protected or drained during freezing weather because the smaller volume of water in the piping will freeze more readily and may split the pipe. Refer to a contractor familiar with these conditions.

- If freezing is a concern, the tank can be insulated with a waterproof insulation or put in an insulated shed.

- An underground tank offers the best protection from freezing. It will also keep the water cool in the summer.